https://tyrilights.com/wp-content/uploads/2024/02/Skarmavbild-2024-02-26-kl.-14.38.38.png

1292

2296

peo

https://tyrilights.com/wp-content/uploads/2019/06/tyri_logo-1.png

peo2024-02-26 14:48:322024-02-26 14:48:32Valtra now offers INTELLilight as part of their Unlimited range

https://tyrilights.com/wp-content/uploads/2024/02/Skarmavbild-2024-02-26-kl.-14.38.38.png

1292

2296

peo

https://tyrilights.com/wp-content/uploads/2019/06/tyri_logo-1.png

peo2024-02-26 14:48:322024-02-26 14:48:32Valtra now offers INTELLilight as part of their Unlimited rangeAt the forefront of innovation, TYRI develops numerous lighting solutions that perfectly match requirements of commercial and heavy vehicles such as trucks and buses.

From headlights and marker lights to reverse lights with E approval options we have a wide selection of products to meet your needs, or we can work alongside your design team to create a light that matches your expectations in both design and performance.

TYRI test and approve all work lights under some of the toughest conditions in the industry to ensure they will not fail. Available in a wide selection of lumen output and voltage options to suit your needs, TYRI is the leading name in heavy vehicle lighting.

With a finger on the pulse of the industry, the TYRI Research and Development department ensure they are ahead of the curve with new technology and trends, developing new solutions to meet these future needs. Read more about the latest lighting technology and how TYRI can help you in our magazine.

Clear Vision

LED reverse lights are generally mounted very close to the ground and must stand rock chips, water, snow, and mud. In this case, TYRI’s LED 0909 reverse lights (R10 / R23) are used to give the driver full vision behind the vehicle. Reverse lights are also available in models 1010 (R10/R23) and VL4 (R148).

Improved Visibility

Improve your driver’s working condition and ensure 100 % visibility when reversing. TYRI LED 1010 to the left and LED 0909 to the right are two product families consisting of both LED work lights and E-rated LED reverse lights, with different lumen output and voltage ranges. Other brackets than standard brackets are available for both lights.

Streamline Design

Design and flexibility are key, not only to the look of your machine but also the effectiveness of the lights. TYRI offer a wide range of lighting to compliment the heavy vehicle included the VL4. This streamline light can be mounted flush to a vehicle or via a bracket and provides effective light without an obtrusive appearance.

Effective Lighting

Driving long timber trucks, especially in poor weather conditions at all times of the day, is a challenge for each driver. During winter months, snow covered ground creates intense glare with the average reflection of light over the field of view being very high, in the range of 70-90%. But also rain and hail makes driving difficult. Ask TYRI for advice what is best for you.

Extend the Life of your Work Lights

Cooling fins can become extremely hot when they are dirty, this causes the built-in overheating protection to be activated on to lower the lumen output and heat. TYRI LED work lights can switch off automatically to prevent damage and switch on again when the dirt has been removed from the cooling fins. Therefore it is essential that you clean your LED work lights regularly.

Testing and Approvals for Heavy Vehicles

EMC EN55025 / CISPR 25

EMC EN55025 / CISPR 25

It is of vital importance, especially on emergency or military vehicles, that lighting does not affect control systems, cameras, on-board computers and other radio sensitive equipment. This is why TYRI lights are scrutinized to ensure they do not interfere with EMC functionality.

IP 69K

IP 69K

IP 69K ratings offers complete peace of mind that the work light you are installing has undergone rigorous tests to ensure it is both durable and conforms to the highest standards on the scale of protection against water, moisture and dust ingress.

Vibration testing

Vibration testing

TYRI lights undergo extensive vibration testing, for up to 8 hours on all axes, above 10 Grms at a frequency range from 5 – 2000 Hz. This simulates the forces applied to the lights once mounted on off highway machines.

Salt spray testing

Salt spray testing

TYRI lights undergo rigorous salt spray testing to ensure they are approved to ASTMB117 standards. This ensures that even in corrosive environments, TYRI lights will continue to perform.

Shock testing

Shock testing

As well as vibration testing, TYRI lights undergo shock testing to a force of 50G. This ensures that TYRI lights will withstand punishment from your work environment.

Environmental testing

Environmental testing

TYRI lights tested in hot and cold temperatures, as well as humidity, for a minimum of 50 days. They are tested in conditions up to -40C° to +85C° and up to 90% humidity.

Polarity / Overheating / Overvoltage Protection

TYRI lights have built in temperature sensing circuits which reduce the output to regulate the temperature of the light. This prevent damage to the LED’s that can result in premature failure. TYRI LED lights are also reverse polarity protected in the event of incorrect installation. Should the wires become crossed during connection, TYRI lights will not turn on until the wires have been connected in the correct configuration, protecting the LEDs and associated circuitry.

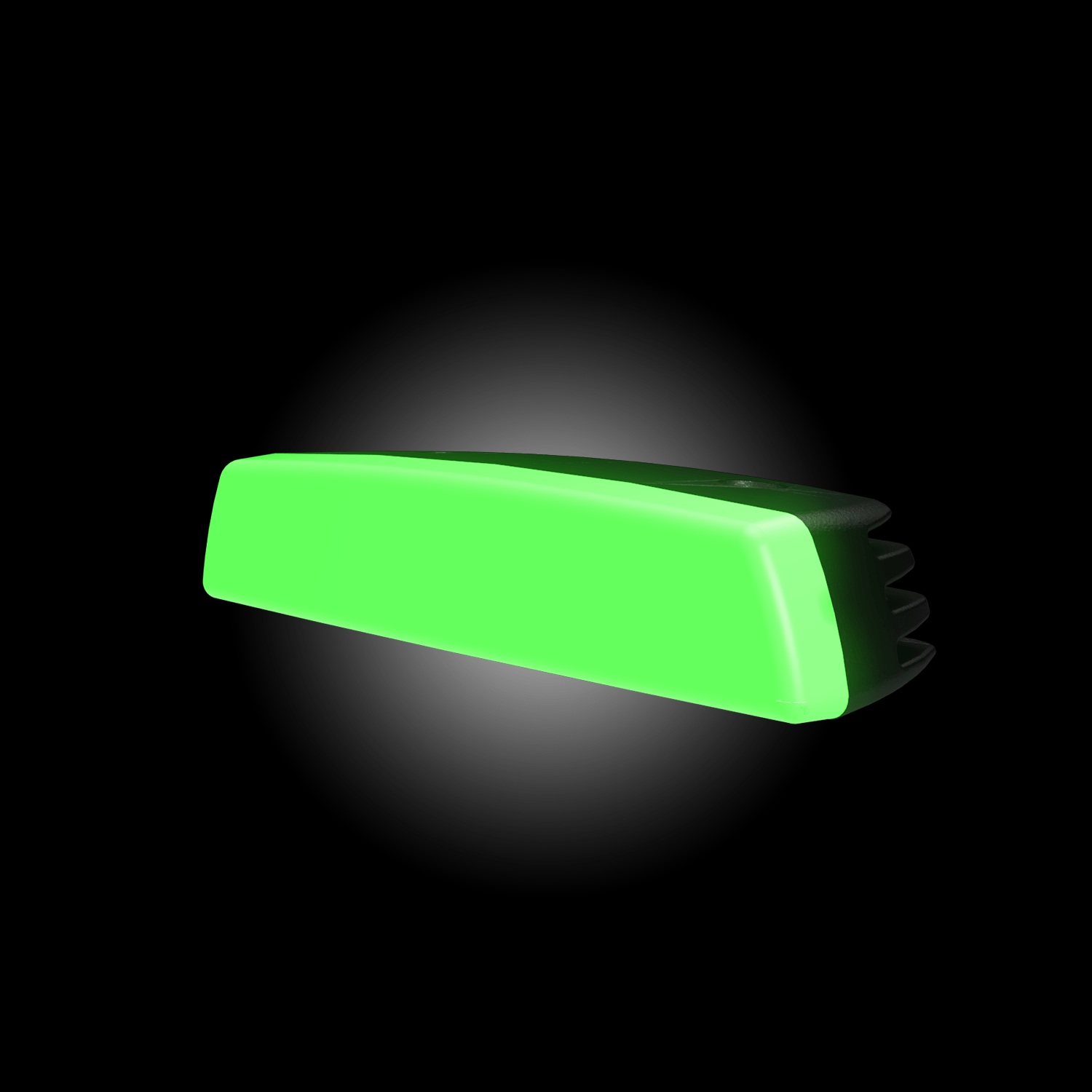

BASEline S1

BASEline S1 INTELLilight

INTELLilight